I plan for this post to be short on words, as it is late, and it is the end of a very long week.

I arrived at the workshop at around 8:00 and got right to installing a number of new electronic goodies in R2. The first order was to get some of the wires from the electronics bay organized, as I was on a mission to add even more sinews to the tangled web of plastic shrouded copper spaghetti.

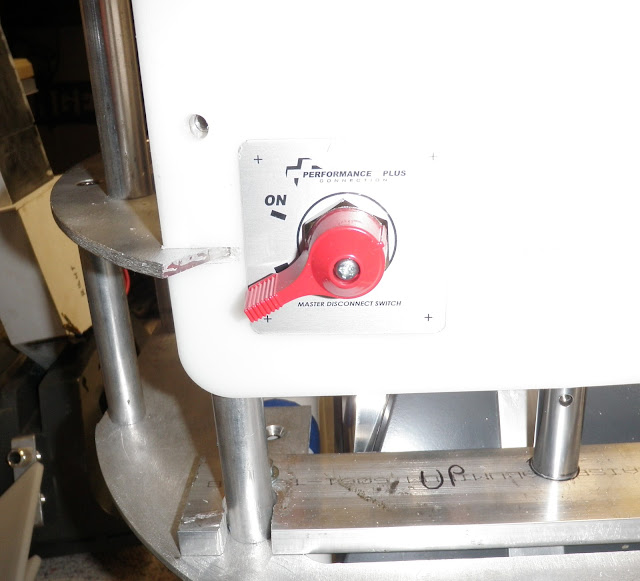

First, I needed to make some room inside the body for the electronic board "annex" that holds the power distribution board and the slip-ring distribution board. I drilled mounting holes in the crossmember of the frame.

A little closer look at what I am babbling about.

These screws then run through the 24V to 12V converter box.

On top of the converter box, I mount the secondary electronics bay.

A little closer look. I am happily surprised I found some bolts that were actually the exact size I needed.

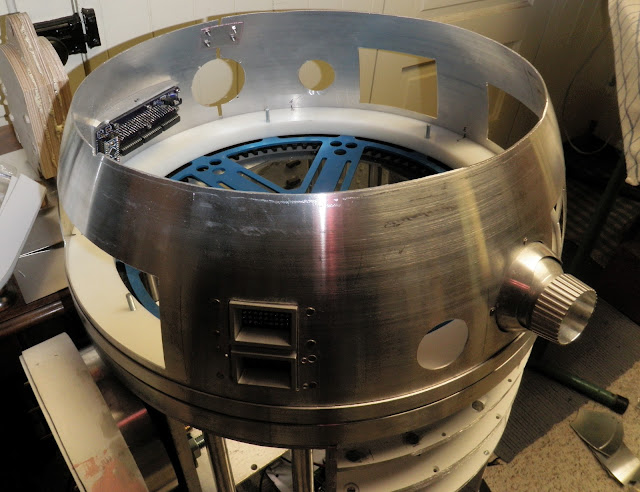

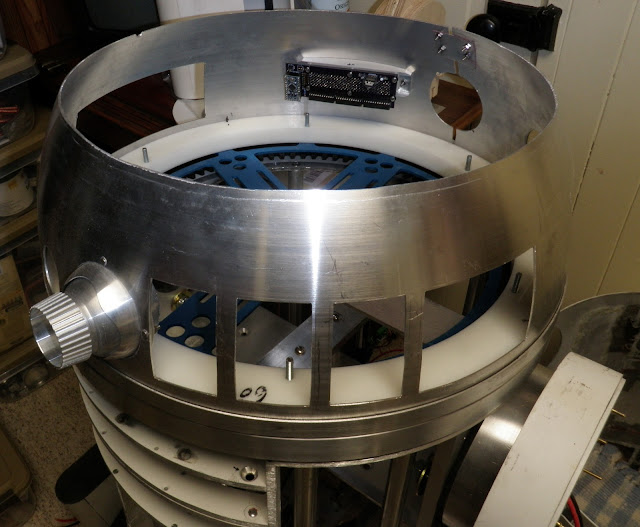

A view from a step back. You can see the parallel port hookup that sends the power to the dome through the slip-ring.

Things are going extremely well at this point. Then - I go to hook up the power lead that goes to the slip-ring, and ..... DARGH .... too short.

Not to worry, a quick 90 degree rotation of the slip-ring board, and the wire fits.

My sound setup. I weighed a lot of options (meaning, I purchased a couple of things... and decided on the bluetooth sound setup). I really fear the coding of the sound boards CFIII or other available sound boards, not to mention hooking up the controls to a 12 or 16 channel receiver. I am very comfortable with the ReSounder IPod touch app that allows you to create unlimited custom soundboards. These soundboards will hold all of R2's beeps and blurts and play through a Bose bluetooth speaker.

Concerned about the range of bluetooth, I found a bluetooth range extender. This extender reportedly extends the range of a bluetooth signal from the default 10 meters to a whopping 100 meters. So, I bypass the Bose bluetooth speaker, use the Miccus Range Extender as a receiver, and use the audio output to plug into the aux jack in the back of the bluetooth speaker (now simply a powered speaker with the bluetooth disabled). I gotta say, this thing just works. Upon testing, I had the speaker inside of R2, turned it up, went to the second floor of the house and heard him beeping away in the basement. So far, I am really impressed with the range of this device.

The unit is small, and can be used to transmit or receive a bluetooth signal. I put the device in receive mode, literally in a second, it is hooked up with my iPod touch. Most bluetooth devices take a while to sync up with your source, I have to believe with the strength of the boosted signal, it locates the iPod and hooks up really quickly.

Here is a shot of the back of the range extender with the various audio outputs and inputs. Again, I am using the device in output mode (as a receiver) - and sending the signal to the Bose speaker through the Line Out / Rx Audio Out jacks.

Gotta have some power for the extender and the speaker. I picked up a Motorcycle USB power supply that accepts input from 6-24 volts and outputs a 5 volt usb connection.

The Bose speaker did not have a power option via USB, so I picked up a car charger for the speaker, and hooked it up to a 12 Volt car power supply port.

Happy/dumb luck experience #422 : the bluetooth extended fits in the cutting board handle perfectly. Like it was meant to be there all along. The video below shows how this fits in the top of the electronics bay.

A shot from the front, showing the speaker mounted behind the utility arm bays. I figure that the Large Data Port opening right below the dome will allow a good amount of sound to escape from the body once the skins are attached. Oh yeah... the skins. I have still not attached the skins to see if all this work actually FITS inside the little guy. If it does not, I presume a Hiroshima-style F-Bomb will be heard far and wide. Keep your ears peeled.

And as mentioned earlier, here is a video of all the powered up goodies working in unison. I still have to adjust the new motor holders and casters, as they are not performing well now.

... and last but not least - a set of yummy aluminum spacers from Al Eisenmann from the Astromech boards. Al and his family (and his R2) were honored with an appearance in an upcoming WIRED magazine article. Kudos to Al and his family for this experience !

And a SWEET video featuring a number of my 501st brothers and sisters.

A little surprise with the set of spacers - R2-D2 Builders Club sticker !!!! (It's all about the swag in case you did not hear).